A research group Professor Yoji Miyajima and Professor Kazuhiro Ishikawa of Faculty of Mechanical Engineering, Institute of Science and Engineering, Kanazawa University, Ryota Tatsumi, Division of Mechanical Science and Engineering, Graduate School of Natural Science and Technology (at the time of the research), Professor Naoki Takata of Nagoya University, and Professor Hiroki Adachi of the University of Hyogo, has demonstrated that low-temperature annealing (heating) of aluminum-iron (Al-Fe) alloys produced using a metal 3D printer at temperatures below 300°C can simultaneously improve the electrical and thermal conductivity, as well as the mechanical properties.

The Laser Powder Bed Fusion (L-PBF) method (*1) has been attracting attention as an innovative manufacturing method that enables the rapid fabrication of components with complex shapes by applying metal 3D printer technology. However, Although rapid cooling forms a supersaturated solid solution to achieve high strength, it has problems with reduced electrical conductivity and residual stress (*2).

In this research, we have presented a new heat treatment guideline for controlling nanoprecipitation (*3) by annealing at relatively low temperatures to relieve residual stress while increasing electrical conductivity. The research results are expected to establish a new heat treatment guideline that eliminates internal residual stress while increasing electrical conductivity, leading to the development of next-generation mobility electronics cooling technology, in addition to applications that contribute to improved energy efficiency, such as lightweight structural components and highly efficient heat dissipation components.

The results of this research were first published in the online edition of Elsevier's international "Journal of Materials Research and Technology" on November 14, 2025, and officially published on November 18, 2025.

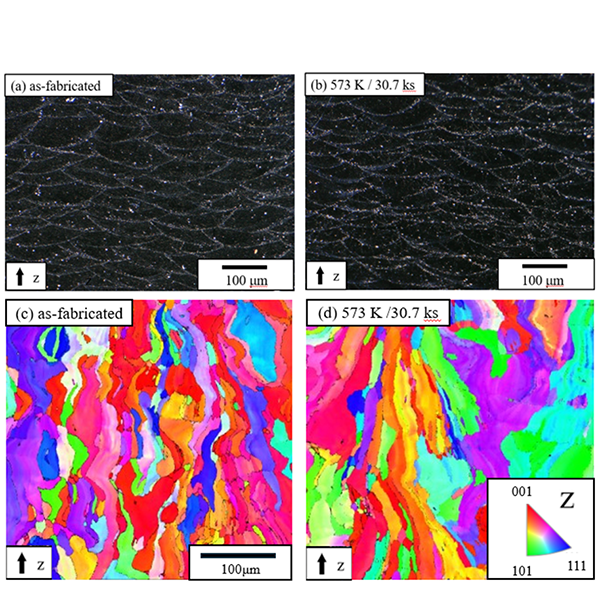

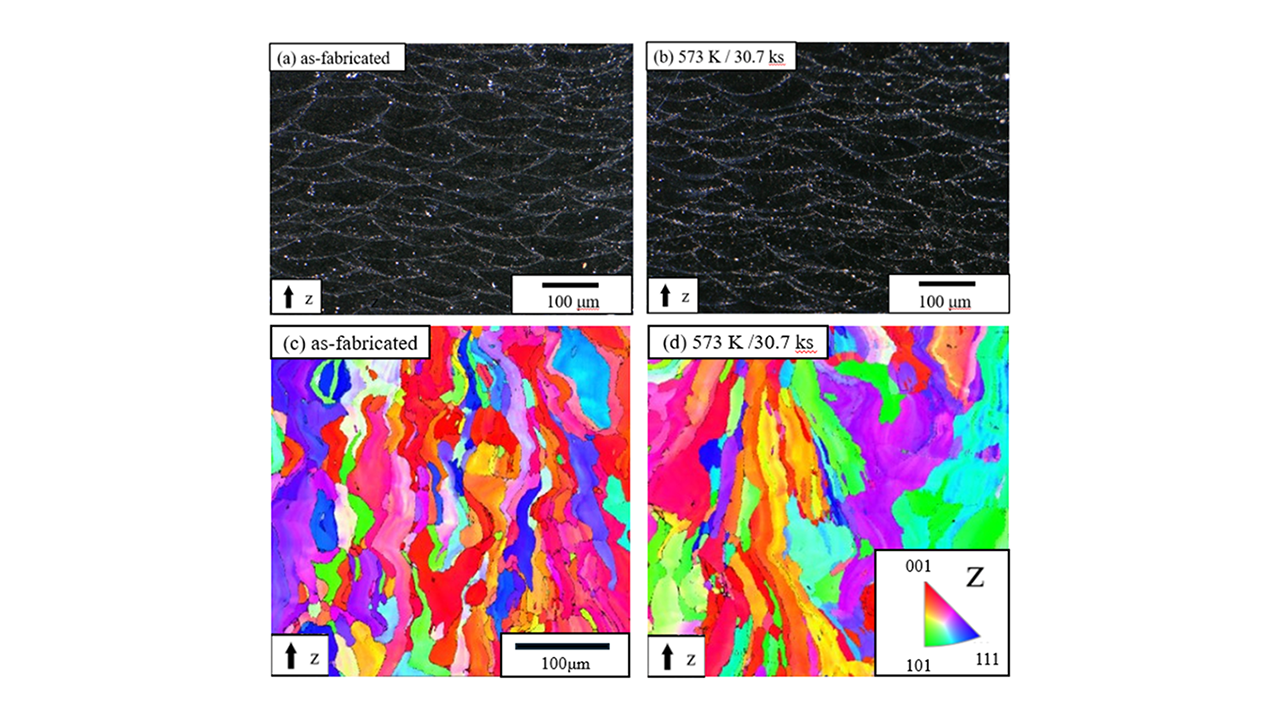

Figure: Optical microscope images showing the molten pool structure and the corresponding crystal grains in (c, d), respectively. (a, c) show samples immediately after modeling and (b, d) show samples annealed at 300 °C for a long time.

【Glossary】

*1 Laser powder bed fusion (L-PBF) method

A type of 3D printer technology in which metal powder is placed one layer at a time and selectively melted and solidified by laser. This technology is suitable for complex shapes and small lot production, and has been attracting attention in the aerospace and medical fields in recent years.

*2 Residual stress

Residual stress is invisible stress that remains inside a material after forming or processing. It is important to remove it because it causes deformation and cracking.

*3 Nanoprecipitates (Al₆Fe)

Metallic compounds of several nm to several tens of nm size that precipitate in the matrix phase. It improves strength by inhibiting dislocation movement, and improves conductivity by reducing supersaturated solid solution atoms. (1 nm is one millionth of a millimeter.) In this study, Al₆Fe is the nanoprecipitate.

Click here to see the press release【Japanese only】

Journal : Journal of Materials Research and Technology

Researcher Information : Yoji Miyajima

Kazuhiro Ishikawa

Related Information

Kanazawa University College of Science and Engineering : https://www.se.kanazawa-u.ac.jp/en

Kanazawa University Graduate School of Natural Science and Technology : https://www.nst.kanazawa-u.ac.jp/

PAGE TOP

PAGE TOP