- Home

- Highlights

- Ultrasound and ionic liquid

Highlights

Ultrasound and ionic liquid: Synergies enhance pretreatment of lignocellulosic materials

Lignocellulosic materials such as waste wood and agricultural residues have attracted interest in the search for alternatives to fossil fuels. Hydrolysis and subsequent fermentation of lignocellulosic materials provides useful biofuels. Now Nobuaki Shimizu and colleagues at Kanazawa University in Japan have reported that they have drastically enhanced enzymatic hydrolysis of cellulose using an ultrasonic pretreatment of the lignocellulosic material in so-called ionic liquids—organic salts with a melting temperature below 100°C.

Lignocellulose is found in plant cell walls. It contains cellulose, hemicellulose and lignin in rigid crystalline structures that impede access to enzymes. Pretreatments to disrupt these structures should improve the efficiency of the subsequent reactions. However the pre-treatments attempted so far, have been either impractical or ineffective, or have led to the formation of unwanted polysaccharide degradation products, which impinge on the overall sugar yields available for fermentation.

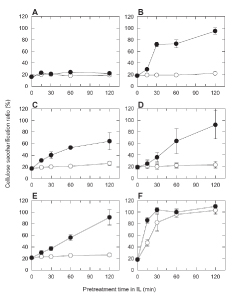

Ultrasound has been effectively used in slurry mixing on account of the high and low pressure waves generated, as well as other effects attributed to high temperatures caused by imploding cavitation bubbles. On the other hand ionic liquids have proved useful solvents for a range of materials under mild conditions, including non-polar organic, inorganic and polymeric compounds. Kenji Takahashi, Nobuaki Shimizu and their colleagues at Kanazwa University investigated the effects of ultrasound pre-treatments on the lignocellulosic material ‘kenaf powder’ in five different ionic liquids.

The researchers quantified the efficiency of hydrolysis using a quantity termed ‘the saccharification ratio’, obtained by comparing the cellulose hydrolysed into glucose with the cellulose recovered from the kenaf powder following the pre-treatment. They concluded, “The combination of ultrasound and ionic liquids synergistically enhanced the cellulose saccharification ratio of kenaf powder.” The treatment yielded an improved cellulose saccharification ration of approximately 39–75% compared to conventional thermal treatments.

Reference

Enhanced enzymatic saccharification of kenaf powder after ultrasonic pretreatment in ionic liquids at room temperature. Kazuaki Ninomiya 1*, Kazuki Kamide 2, Kenji Takahashi 2*, Nobuaki Shimizu 1, Bioresource Technology 103, 259–265, (2012). Link

Affiliations

1. Institute of Nature and Environmental Technology, Kanazawa University, Kakuma-machi, Kanazawa 920-1192, Japan

2. Division of Material Engineering, Graduate School of Natural Science and Technology, Kanazawa University, Kakuma-machi, Kanazawa 920-1192, Japan

Chemical Reaction Engineering Kenji Takahashi Lab.

*corresponding authors, email address: ktkenji@t.kanazawa-u.ac.jp (K. Takahashi), ninomiya@t.kanazawa-u.ac.jp(K. Ninomiya)

ID: 201212A010