Abstract: Kanazawa University researchers experimented with different combinations of zwitterionic molecules to produce a solvent that is liquid below 100°C and very effective at breaking down cellulose. This research may lead to much more cost-effective and safe production of biofuels, such as ethanol from switchgrass or plant husks.

Kanazawa, Japan – Scientists from the Institute of Science and Engineering at Kanazawa University have developed new solvent mixtures to break down the tough structure of plant cellulose for the production of bioethanol. These new solvents work under mild conditions, have reduced toxicity and are more environmentally friendly compared with currently available solvents. This work may lead to improved technologies for the conversion of currently unused biomass to fuel.

Biofuels, such as ethanol produced from switchgrass or sugarcane, may allow us to reduce our reliance on nonrenewable fossil fuels. However, the process of making biofuels usually requires breaking down the cellulose from plants, which consists of long polymer chains, into smaller sugar molecules. This is not a simple task, as illustrated by how unappetizing tree bark or grass stalks look to us humans. Cellulose has a complex hydrogen bonding network, which makes it extremely chemical resistant. Current methods for processing cellulose rely on harsh reaction conditions and toxic chemicals.

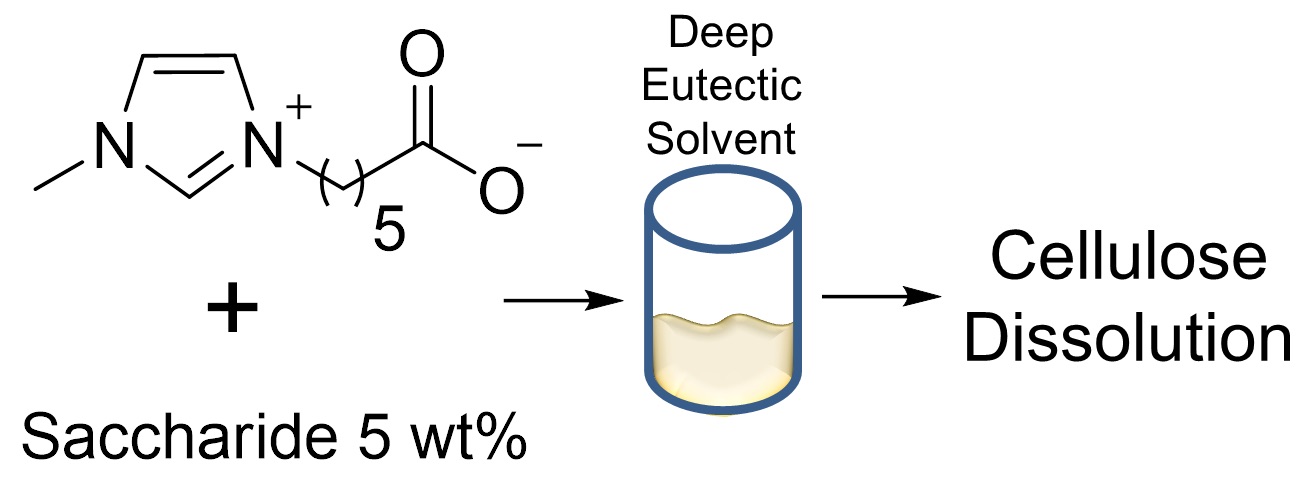

Now, scientists from Kanazawa University have used a special class of molecules called “zwitterions” to create novel solvents with the ability to dissolve cellulose. Zwitterions are special in that they have both a positive and negative charge, but at different locations on the molecule so they cannot neutralize each other. These charges are highly effective at disrupting the hydrogen bonds keeping the cellulose from being broken down. “Because almost all zwitterions are solid under normal reaction conditions, our experiments used eutectic mixtures,” first author Gyanendra Sharma explains. A eutectic system is a mixture of substances with a melting point lower than that of its constituent parts. This is accomplished by using molecules with different structures, so that regular crystals are harder to form.

In these experiments, the team mixed four different zwitterions at various ratios. They found 22 combinations that were liquid below 100°C. Of these, two mixtures were also highly effective at dissolving cellulose. “Our work shows that it is possible to replace many of the toxic chemicals used today with more environmentally friendly alternatives as we move towards a more renewable energy ecosystem,” senior author Kosuke Kuroda says. This research demonstrates the potential of using combinations of zwitterions to create mixtures with properties not possessed by any molecule individually.

Figure

Suitable solvents are needed to produce ethanol from cellulosic plant biomass. We have found that liquid zwitterions are suitable for it, but it has been difficult to liquefy zwitterions and the species have been strictly limited. Therefore, the solid zwitterions were liquefied through making deep eutectic solvents, which are liquids from solid-solid mixtures. The liquefied zwitterionic solvent was able to dissolve the cellulose.

[Funder]

This study was partly supported by KAKENHI (18K14281 from the Japan Society for the Promotion of Science), and the Leading Initiative for Excellent Young Researchers (from Ministry of Education, Culture, Sports, Science and Technology-Japan). This research was also partly supported by the COI program “Construction of next-generation infrastructure using innovative materials–Realization of a safe and secure society that can coexist with the Earth for centuries”, which is supported by Ministry of Education, Culture, Sports, Science and Technology-Japan and Japan Science and Technology Agency and Kanazawa University Sakigake project 2020.”

[Article]

Title: Polar zwitterion/saccharide-based deep eutectic solvents for cellulose processing

Journal: Carbohydrate Polymers

Authors: Gyanendra Sharma, Kenji Takahashi, Kosuke Kuroda

PAGE TOP

PAGE TOP